Electrical Division

Combination Phase Converter/ Motor Controller

Power Factor Improvement Capacitors

Threaded Pipe Nipple Division

RotaDyne

Except with products where accessory duplication might occur, Willett phase converters include all the components needed for safe and immediate operation. Such things as starters, selector switches, and overload protectors are often not included with many other manufacturers. These exclusions are expensive to the consumer. They involve further purchases, time delays, and installations by skilled technicians. Willett believes that whenever possible, a complete factory installed component package is in the best interest of our customers. In the first place, it's cheaper to have these components installed at the factory level. Secondly, factory installed components maintain a homogenous integrity that aftermarket purchases lack. You're assured your factory-installed components reflect a quality consistent to the rest of your converter and you know a technician familiar with the procedure has installed them. All RotaDynes come complete with a starter package

.

The efficiency of three phase power and the range of electric motor choices it accommodates are a desirable combination for many job applications. Not only can you operate much larger motors with three-phase power, but the simple construction of three-phase motors reflects less cost, maintenance and breakdown. These motors are more readily available than single-phase, and are lighter, smaller, and come in a variety of enclosures. The obstacle to three phase motors is the need of three-phase power, which is not always accessible and/or cost effective. Phase converters provide an inexpensive access to three-phase power and all it's advantages.

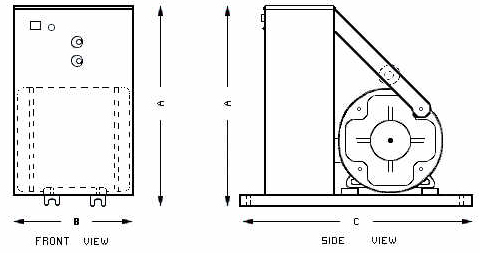

RotaDyne is a rotary phase converter. This is a moving phase converter consisting of a rotating transformer and control panel. The RotaDyne can virtually operate an unlimited amount of motors working individually or simultaneously. It runs the motor(s) at full 100% nameplate horsepower rating, and provides efficiency almost that of running the motor(s) from a three-phase service. Three-phase motors operate at their normal efficiencies regardless of frequent starts, reversing and varying or variable speeds. Multi-speed motors can be operated normally.

When a RotaDyne is used the single-phase power line only sees about 50% of the starting current of the three-phase motor started. The other 50% are made up in the spinning rotor of the converter. This results in negligible line disturbances.

Sizing

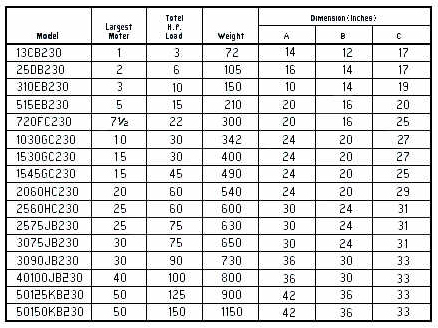

The following chart will help you choose the right RotaDyne for your application. This chart shows the model number for an incoming voltage of 230. If your supply voltage is other than 230, the last three model numbers will change to either 460 or 600 to reflect your requirements.

Example: 13CB230 indicates 230 voltage 13CB460 indicates 460 voltage 13CB600 indicates 600 voltage

Model Number |

Largest HP - Single Motor |

Combined HP - All Motors |

| 13CB230 | 1 | 3 |

| 25DB230 | 2 | 6 |

| 310EB230 | 3 | 10 |

| 515EB230 | 5 | 15 |

| 720FC230 | 7.5 | 22 |

| 1030GC230 | 10 | 30 |

| 1530GC230 | 15 | 30 |

| 1545GC230 | 15 | 45 |

| 2060HC23 | 20 | 60 |

| 2560HC230 | 25 | 60 |

| 2575JB230 | 25 | 75 |

| 3060JB230 | 30 | 60 |

| 3090JB230 | 30 | 90 |

| 4080JB230 | 40 | 80 |

| 40120JB230 | 40 | 120 |

| 50100JB230 | 50 | 100 |

| 50150KB230 | 50 | 150 |

To use this chart, you must first determine the horsepower of the largest single motor you will be using in the application. Next, you need to calculate the combined horsepower of all three-phase motors that will be used on this application. As an example, you might have a situation where you want to operate four motors off of one RotaDyne. You have (3) - 1 horsepower motors and (1) - 3 horsepower motor, and your incoming voltage is 460. In this case your largest single horsepower is 3 and your combined horsepower is 6. Model number 310EB460 most closely suits your requirements as it can accommodate a 3 horsepower motor, as well as a combined horsepower of 10. If you have a situation where your combined motor horsepower exceeds that listed in the chart, you must accommodate the combined size. As an example, (6) - 3 horsepower 460 volt motors require a 720FC460. Even though the largest single motor is only 3 horsepower the combined horsepower is 18, which falls within the combined horsepower range of the 720FC460. NOTE: There are times when your motor voltage is other than that of your incoming voltage. If you run into this situation, please contact the factory as adjustments will have to be made to your RotaDyne. We encourage you to contact the factory with any questions you have about choosing the proper RotaDyne for your situation.

Technical Information

Current

To determine the size of the single-phase service and wiring, add up the total three-phase load in amperes, multiply by 1.732 and add any single-phase load that may be operated. Apply local regulations to these amperages to select the proper wire sizes. The following charts demonstrate amperages and wire size for each model.230 VAC RotaDyne

Model # |

1 Phase Input Amperage |

3Phase Load Amperage | RotaDyne Starting Amperage | 1 Phase Disconnect (A) | 3 Phase Disconnect (B) | RotaDyne Wire Size |

13CB230 |

17 | 10 | 30 | 30 | 15 | 12 |

| 25DB230 | 29 | 14 | 50 | 30 | 15 | 12 |

| 310EB230 | 50 | 28 | 60 | 60 | 30 | 10 |

| 515EB230 | 72 | 42 | 100 | 100 | 60 | 6 |

| 720FC230 | 94 | 54 | 250 | 100 | 60 | 6 |

| 1030GC230 | 138 | 80 | 280 | 200 | 100 | 2 |

| 1530GC230 | 138 | 80 | 300 | 200 | 100 | 2 |

| 1545GC230 | 200 | 117 | 320 | 200 | 150 | 1/0 |

| 2060HC230 | 266 | 154 | 400 | 300 | 200 | 3/0 |

| 2560HC230 | 266 | 154 | 425 | 300 | 200 | 3/0 |

| 2575JB230 | 332 | 192 | 450 | 400 | 200 | 3/0 |

| 3060JB230 | 266 | 154 | 425 | 400 | 200 | 3/0 |

| 3090JB230 | 400 | 234 | 600 | 400 | 300 | 4/0 |

| 4080JB230 | 350 | 204 | 570 | 400 | 300 | 4/0 |

| 40120JB230 | 500 | 290 | 650 | 500 | 300 | 4/0 |

| 50100JB230 | 430 | 248 | 650 | 500 | 300 | 4/0 |

| 50150KB230 | 622 | 360 | 750 | 600 | 400 | 500MCM |

| Model # | 1 Phase Input Amperage | 3 Phase Load Amperage | RotaDyne Starting Amperage | 1Phase Disconnect (A) | 3 Phase Disconnect (B) | RotaDyne Wire Size |

| 13CB460 | 9 | 5 | 15 | 30 | 15 | 12 |

| 25DB460 | 15 | 9 | 25 | 30 | 15 | 12 |

| 310EB460 | 25 | 14 | 30 | 30 | 15 | 12 |

| 515EB460 | 36 | 21 | 50 | 60 | 20 | 12 |

| 720FC460 | 47 | 27 | 125 | 60 | 25 | 10 |

| 1030GC460 | 69 | 40 | 140 | 100 | 30 | 8 |

| 1530GC460 | 69 | 40 | 150 | 100 | 60 | 8 |

| 1545GC460 | 100 | 59 | 160 | 100 | 60 | 6 |

| 2060HC460 | 135 | 78 | 185 | 150 | 60 | 4 |

| 2560HC460 | 135 | 78 | 190 | 150 | 100 | 4 |

| 2575JB460 | 166 | 96 | 225 | 200 | 100 | 2 |

| 3060JB460 | 135 | 78 | 200 | 200 | 100 | 2 |

| 3090JB460 | 200 | 117 | 250 | 200 | 100 | 1/0 |

| 4080JB460 | 173 | 102 | 250 | 200 | 150 | 1/0 |

| 40120JB460 | 250 | 145 | 300 | 250 | 200 | 2/0 |

| 50100JB460 | 214 | 126 | 320 | 300 | 200 | 2/0 |

| 50150KB460 | 311 | 180 | 345 | 300 | 200 | 3/0 |

Efficiency and Power Factor

The efficiency of three phase motors operating on the RotaDyne is not changed by any appreciable amount. The overall power factor for the motor-converter combination is considerably higher than that of the same three-phase motor alone. This causes a reduction in the starting amperage, and as a result, has less effect on the power line. When the motors are operating under normal load conditions the overall power factor will be near unity. This is an ideal power load from the power supplier's standpoint, since all of the amperage serves as useful power.

Torque

The RotaDyne phase converter is equipped with a unique starting cycle, which always allows it to start under mechanical or weather problems. Electric motors operated on phase converters can experience some torque limitations because overloads and starting currents cause the voltage of the produced phase to drop. When operated on a RotaDyne, 1800 RPM and 1200 RPM electric motors suffer only slight decreases in starting torque. On motors of 3600 RPM and 900 RPM, considerable less starting torque is developed but still adequate for the average application. To overcome heavily loaded motors with starting problems:- Select the next size larger RotaDyne.

- Add extra Running Capacitors directly to the Motor Starter.

- Add starting booster package directly to the Electric Motor Starter.

- Select an electric motor with Design C or D starting torque characteristics, since the electric motor may not have enough starting torque for the application.

Motor Protections

Overload protection is supplied in all three legs of the RotaDyne and is arranged for manual reset. It is recommended that the electric motors be controlled by a magnetic starter complete with overload protection in all three legs.

The Standard RotaDyne

The Standard RotaDyne is designed for mounting indoors under relatively dry conditions. The unit is not to be operated under driving rain or snow conditions, although the rotating transformer is of a drip-proof nature and the control panel is housed in a CEMA 12 enclosure and can be stored outdoors. Standard voltages are 230 or 460 VAC. The RotaDyne comes with manual Stop-Start Operation.

Options

Enclosures: Weatherproof and Dust-tight enclosures are available on request.

Voltage: 600 VAC units are available upon request.

Voltage Transformer: Voltage transformers are available for special applications. A voltage variation of more than 10% above or below the normal rating will affect both the converter and system.

Capacitor Ballasts: Ballast packages are available from the factory if required. These are additional capacitors added directly to a motor that has insufficient produced phase voltage.

Remote Control: RotaDynes can be factory wired for operation from multiple remote controlled locations, upon request. Wiring diagrams for field wired remote controlled RotaDynes are available with standard production units upon request.

Automatic Start: Special construction is available for automatic start-up applications.